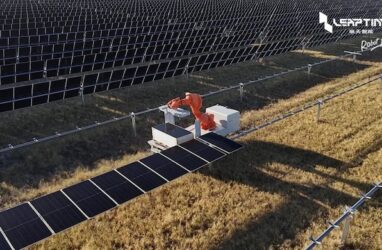

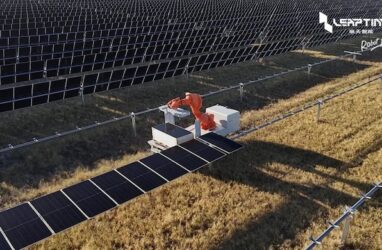

A Chinese tech company says it has completed its first solar module mounting contract with an AI-controlled robot in Australia, helping to carve 25 per cent off the project delivery time, and doing the job of three to four humans. The Chinese company Leapting says its Litian Intelligent robot was deployed at Neoen’s Culcairn solar farm in NSW – where it installed 10,000 solar modules at its first commercial deployment, and it has hailed the effort as a success. Work started in February with imagery showing the machine lifting panels weighing up to 30 kilograms from a stack and placing them gently into a bracket.

The 2.5m high robotic arm sits on a self-guided, self-propelled crawler that is equipped with a navigation system, and visual recognition technology so it can adapt to different terrain and environmental conditions, and multi-modal 3D sensors to ensure the panel goes in the right place. “The installation efficiency has increased by 3-5 times compared to manual operations,” Leapting said.

Leapting was founded in 2022 in Shanghai and builds smart cleaning tech for solar panels and the installation robot. It is not the only company doing this however: venture capital tracking site Traxn says there are 117 active competitors in this market, including Kyocera, Trina Solar and Suntech Power. The idea behind building a robot to install panels in large solar farms is to address the challenges of scale and distance, the cost of labour, and – in a country like Australia – heat.

The sheer number of panels required for supersized solar farms – the 350 megawatt (MW) Culcairn will have just under 760,000 once it’s finished by mid-2025 – and the growing size of individual modules are key factors that put a burden on manual installation methods. “At the same time, large-scale ground-mounted power stations are usually located in remote areas, with harsh construction environments and strong sunlight, which further increases the safety risks and uncertainties in the construction process,” Leapting says. The hope is that using a robot to do this part of the installation will sidestep worker shortages and reduce downtime caused by injury.

Leapting says solar modules weighing up to 30kg require three to four people to handle, which it works out to as an installation rate of about 90-120 modules in an eight-hour day. The company says its robot can install three to five times more than this at about 60 modules an hour, helping to reduce overall solar farm construction times by at least a quarter. Neoen had some 600 people on site in December during the peak construction period, the developer said in its February update.

It will now deploy the robot and several others to another Australia solar farm to start work in May, installing some 500,000 panels, once debugging and performance testing has taken place. Neoen, which has agreed to an $11 billion takeover from Brookfield Asset Management, is building the Culcairn solar farm in New South Wales’ (NSW) Riverina district after landing an underwriting agreement with the state government. It also operates the Western Downs solar farm in Queensland, and the Coleambally, Griffith, Parkes and Dubbo solar farms in NSW, along with a number of wind farms and big battery assets in NSW, Queensland, Victoria and Western Australia.

In December, to continue building out its Australian solar, wind and battery projects, including Culcairn, and the 341 MW, 1363 MWh stage 2 of the Collie battery, which will form part of the country’s biggest battery in Western Australia..

Technology

Chinese robot does job of three to four humans installing thousands of panels at Australian solar project

Chinese company says its robot solar mounting machine can install solar panels at three and five times faster than a team of humans, and slash construction times.The post Chinese robot does job of three to four humans installing thousands of panels at Australian solar project appeared first on RenewEconomy.